Predictive maintenance (PM) is a key tool for Industry 4.0, helping companies maximize their system’s efficiency and reduce unplanned downtime. PM enables precise maintenance planning and accurate estimation of a component’s remaining useful life (RUL). This enables you to proactively decide when a component actually needs to be replaced, rather than following a rigid maintenance plan or waiting until a failure occurs. Unplanned maintenance is not only costly but also poses a significant risk to productivity. With proactive maintenance strategies, organizations can extend machine lifetime while reducing maintenance costs.

In this blog entry, we explain the fundamentals of PM, the crucial role artificial intelligence (AI) plays in the process and why this topic is becoming more important across many industries.

Efficient Maintenance with Predictive Maintenance

Traditional maintenance methods typically fall into two categories: preventive and reactive. Preventive maintenance follows a fixed schedule, regardless of whether a component actually has a problem or not. While this approach can prevent unexpected failures, it often results in unnecessary maintenance effort and early component replacements. Reactive maintenance, on the other hand, only takes action after a failure occurs. Both approaches have their own shortcomings: either maintenance costs rise unnecessarily or the likelihood of operational disruptions increases.

PM solves this challenge by introducing predictive, data-driven maintenance. The aim is to only carry out maintenance when it is actually required. Sensor, such as temperature, pressure, vibration or sound, are used to record and analyze machine data in real-time to detect early warning signs of potential failures. The aim is to identify potential problems before they escalate and predict exactly when maintenance is truly needed to avoid unnecessary maintenance costs and downtime.

The Role of Artificial Intelligence in the Predictive Maintenance Process

Predictive maintenance relies heavily on advanced data analysis and machine learning (ML). AI-powered models learn systems, complex patterns and how to detect anomalies in sensor data, especially for systems which were previously linked with failures or errors. These models not only analyze algorithms of individual parameters, they also combine multiple features as warning signals often only emerge when several data points are analyzed together. These features often need to be transformed so that the anomalies can be identified.

Once an anomaly is detected, the system can predict maintenance needs and trigger an alert. Machines are often part of a larger production process, which enables preventive measures, such as controlled shut down of a production line to avoid secondary damage or product losses. This predictive analysis enables maintenance to become flexible and demand-based, which significantly reduces the risk of unplanned failures to an extent which monitoring carried out by humans alone never could. The following graphic shows the AI-supported process predictive maintenance runs through.

What Challenges are There?

PM sounds so promising but there are often many challenges to be faced by companies when actually using it.

- Using Edge Devices: Production machines often operate in environments with limited network connectivity, making data transmission and processing difficult. Edge devices solve this by processing data locally. This reduces latency times and enables quick reaction times to possible problems; their limited computing capacity remains a challenge.

- Limiting Networks: In large production facilities, centralizing and evaluating all machine data can be challenging. Different machines and systems may not be fully integrated. It is challenging to efficiently network this data and create meaningful analyses in spite of fragmented system landscapes.

- Data Security and Protection: PM requires access to sensitive machine and production data. Special data protection measures are essential to protect data upon transfer and storage, especially when data is transferred via the internet or stored in external clouds.

Which Data can I Monitor?

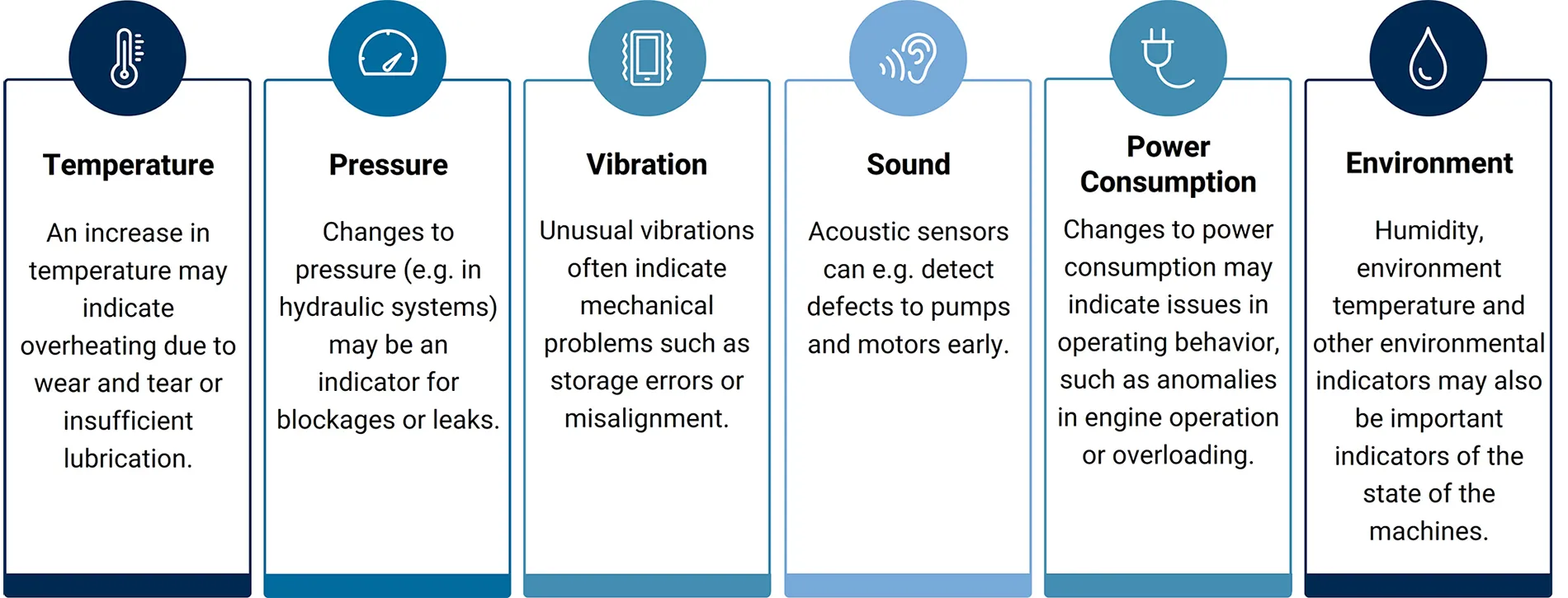

Predictive maintenance draws on a wide variety of sensor data, which fulfill special requirements depending on industry and machine type. This basically applies: Every machine type and industry relies on different measurement parameters to detect potential failures reliably. The data recorded varies depending on the component being monitored and the errors which need to be identified. Below will describe an excerpt of typical examples for sensor data:

Use Cases – Where Can Predictive Maintenance Be Applied?

Predictive Maintenance is used across numerous industries and machine types. Depending on the complexity of the machines, multiple sensors may be combined to give as much of a complete picture of the state of the machine. Typical use cases include:

- Wind turbines used in energy production: Wind turbines are often located in remote areas and difficult to access. Unplanned maintenance is costly and lengthy, often resulting in extended downtime. By continuously monitoring various data within turbine bearings, potential damage can be detected early. PM identifies vibration patterns indicating cracks or wear, enabling maintenance to be carried out before failures occur.

- Conveyor systems in logistics: Downtime for conveyor belts in the logistics industry can result in major delays and high costs, particularly in automated warehouses. Sensors monitor belt speed, motor performance and temperature. Changes in energy consumption or unusual temperature patterns may indicate emerging issues, allowing maintenance to be carried out before operations are disrupted. This means that unplanned failures can be avoided and operation runs smoothly.

- Pump systems in the chemical industry: Pump systems in a chemical company operate around the clock and safely transport liquids and chemicals. Failures can halt production and pose safety risks. Sensors continuously monitor parameters such as vibration, temperature and pressure in the pumps. If anomalies are recognized in this data, such as increased vibration, then this may indicate bearing wear or blockages.

Conclusion

Predictive maintenance is far more than just a trend. The strategic solution can minimize production disruptions and reduce long-term maintenance costs. With advances in machine learning and AI, PM is more accurate and reliable than ever before. However, challenges such as integrating edge devices and protecting sensitive data must be carefully addressed. The growing variety of sensor data offers enormous potential but that value can only be fully realized with the right infrastructure and a structured approach.

In the next blog posts, we’ll show you how to prepare the necessary data for PM and which analytical methods can be used. Stay tuned to discover more about the exciting world of predictive maintenance!

Looking to Optimize Efficiency of Your Machinery?

Get in touch with us to learn how predictive maintenance and AI can help you detect potential issues in your production line early. With intelligent decision-making, you can plan maintenance more effectively and prevent unexpected downtime. We’re here to help you streamline your maintenance strategy! Check out the other consulting services we provide for data-driven company and data analytics. Our data experts offer a free initial consultation to chat to our team and discover how we can support you with your data analytics project.